An engine is a mechanical component that converts some form of energy (particularly thermal energy) into mechanical energy. These types of engines are known as thermal engines. Generally, there are two types of engines, EC engine, and IC Engine.

Both IC and EC engines have two types, reciprocating and rotary engines. IC engine stands for Internal Combustion Engine, in which the combustion and combustion of fuel take place inside the engine. It works on the principle that the charge ignites inside a very high-pressure combustion chamber. The two-stroke and four-stroke engines are the most common examples of the internal combustion engine. These engines are most commonly used in automotive, aviation, power generation, and soon.

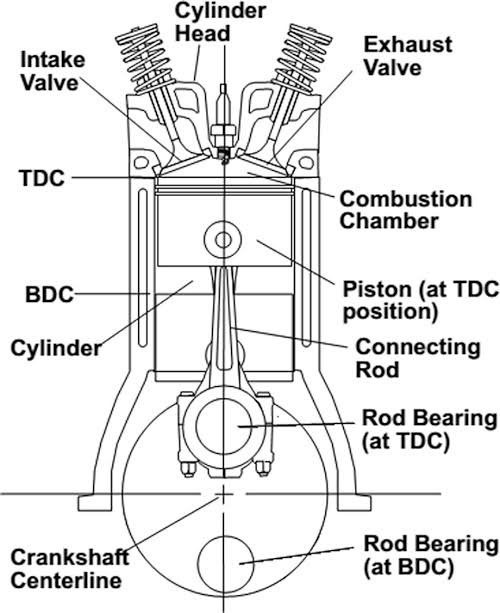

Component of IC Engine

1. Cylinder block

The cylinder is the main body of the internal combustion (IC) engine. The cylinder is the part where fuel consumption, fuel compression, and fuel combustion take place. The main function of the cylinder is to guide the piston. It is in direct contact with the products of combustion, so it should be fresh.

To cool the cylinder, the outside of the cylinder is a water cap (used for the coolant used in most cars) or fins (used to cool the air used in most bicycles). The upper end of the cylinder, the cylinder head, and the lower crankshaft are fastened with bolts. The top of the cylinder is a combustion chamber in which the fuel burns. To control all the pressures and temperatures created by the combustion of the fuel, the cylinder material must have high compressive strength.

2. Cylinder Head

The upper part of the engine cylinder is closed by a removable cylinder head. There are two holes or valves in the cylinder head, one for the air inlet and the other for the exhaust outlet. Both inlet and outlet valves are closed by two valves called inlet and outlet valves. Inlet valve, exhaust valve, spark plug, fuel injector, and so on. These are attached to the cylinder head with bolts. The main function of the cylinder head is to seal the cylinder block and prevent gas from entering and exiting the engine through the cylinder head valve. The cylinder head is usually made of cast iron or aluminum. This is done by casting or forging, usually in one piece.

3. Piston

The piston is mounted on each cylinder as a surface to receive the air pressure and send thrust to the connecting rod. This is the reciprocating part of the IC engine. The main function of the piston is to hermetically rotate the cylinder through the bore and pull it freely into the cylinder.

The piston must be light and strong enough to withstand the pressure of the gas produced by the combustion of the fuel. So, the pistons are aluminum alloy, sometimes cast iron, because light-alloy pistons expand more than cast iron, so they need more distance.

4. Piston Ring

The piston must fit freely into the cylinder so that it can move freely in the cylinder. If the piston is too tight, it will expand as the temperature rises and may adhere tightly to the cylinder. If it is too slow, you will lose the steam pressure.

The piston of the IC engine features a piston ring to create a good seal and low frictional resistance between the piston and cylinder. These rims are installed in the piston grooves. They separate at one end, so they can expand or slide to the end of the piston. Small two-stroke engines have two piston rings for a good seal, but four-stroke engines have an additional ring called an oil ring. The elastic band is made of fine cast iron and highly elastic materials and is not affected by heat. Sometimes made of alloy spring steel.

5. Connecting Rod

The connecting rod connects the piston to the crankshaft and transmits the movement and thrust of the piston to the crankshaft. The reciprocating motion of the piston converts the rotary motion of the crankshaft.

The connecting rod has two heads. One is called the big end and the other is called the small end. The large end is connected to the crankshaft and the small end to the piston via a pin. The connecting rod is made of nickel, chrome, and chrome vanadium steel. For small machines, the material can be aluminum.