If you own a construction site, you may be wondering about the importance of plastic outrigger pads. They come in handy when you’re working with heavy equipment. To help you determine how much weight you need, here are a few tips. First, you need to know how much weight your outriggers can handle. Remember to keep the weight of your equipment and rigging in mind when choosing an outrigger pad.

Outrigger pads are designed to provide large bearing surfaces that evenly distribute the load without damaging the substrate. The plastic shims used by LuxTek are weather-resistant and extremely durable. They have undergone rigorous testing at TUV RheinlandIndustrie Service GmbH. The bigfoot outrigger pad lifespan is based on the material’s strength. This will give you peace of mind. You can use a durable plastic outrigger to prevent your equipment from breaking.

While traditional outrigger pads are constructed of plywood, these can break, crack, and splinter. Replacing plywood can be expensive, and plastic doesn’t splinter, crack, or break. Plastic outrigger pads will last much longer, so you can save money. If you’re looking for a great way to save money while installing outrigger pads, contact Polymershapes. You’ll be happy you did!

Outrigger pads are important for stabilizing heavy equipment. They’re designed to ensure that the outriggers don’t damage the surface underneath. Plastic outrigger pads weigh less than ten percent of steel and won’t rust or splinter like wooden ones do. In addition to their great price and excellent durability, Polymershapes also offers custom designed outrigger pads for specific applications. This type of outrigger pad is a great option for a variety of applications, from construction sites to commercial use.

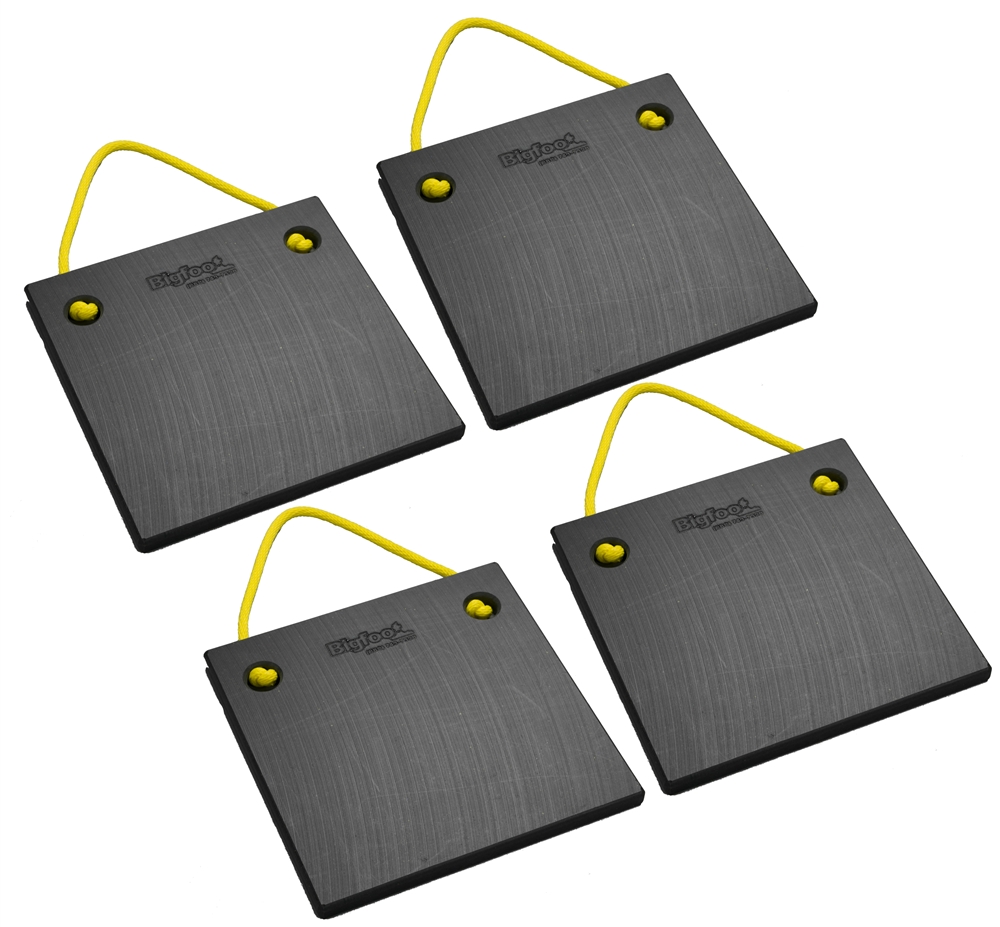

Besides their practical use, outrigger pads also provide safety for your team and equipment. They prevent your equipment from tipping over due to improper support or a lack of traction. Shop bigfoot outrigger pads now from Prime Tech Pads. The outriggers themselves also provide support for the crane. Having the right combination of strength and safety is a must when purchasing an outrigger pad. There is no need to compromise the safety and stability of your equipment because of your inexperienced staff.

Wooden outrigger pads are cheap and easy to find, but they have some disadvantages. In addition to being porous, wood absorbs water, causing the pads to weigh more. Additionally, outrigger pads are constantly exposed to groundwater. This water is full of hazardous substances, including motor oil, road salt, and gasoline. While wood may be easy to replace with an industrial outrigger pad, synthetic pads offer the benefits of durability over cost.